Bridge the Data Gap in Machine Vision AI

Your inspection system is only as strong as the data it's trained on. Prime Studios delivers digital twin synthetic datasets that replicate your inspection environment — camera, lighting, materials, and defects — with photorealistic precision.

Request a Consultation →Why Real-World Data Isn't Enough

Even the best machine vision platforms struggle when training data falls short. Common gaps include:

Rare and Corner-Case Defects

Critical defects that almost never appear in production but could cause catastrophic failures.

Costly or Impossible Samples

Creating defective samples for high-value parts is expensive and often impractical.

Environmental Variation

Changes in lighting, surfaces, reflections, or backgrounds that affect detection accuracy.

Inconsistent Annotations

Missing or poorly labeled data for subtle defects that require expert knowledge.

Domain Mismatch

Differences between controlled lab conditions and messy production environments.

The result: inspection models that fail when reality gets messy.

Our Solution: Digital Twin Synthetic Datasets

We carefully craft digital twins of your parts and inspection environment, replicating real-world conditions with VFX-grade rendering. Each dataset is engineered to:

Supplement Real-World Data

Generate rare defects and controlled variations that are impossible to capture naturally.

Perfect Ground Truth Annotations

Deliver pixel-perfect segmentation, labeling, and defect classification data.

Close the Domain Gap

Ensure your AI performs reliably in production, not just in controlled lab environments.

With nine years of aerospace machine vision experience, Prime Studios combines engineering precision with Hollywood-level realism.

Proven Results

Real-world impact across industries using synthetic training data

Learn more about the quantitative benefits of synthetic training data

Download White PaperPerformance Comparison

Measurable improvements in AI model performance metrics

| Metric | Real Data Only | Real + Synthetic Data |

|---|---|---|

| Precision | 77.46% | 82.56% |

| Recall | 58.06% | 61.71% |

| Mean Average Precision | 64.50% | 70.37% |

| F1 Score | 0.662 | 0.705 |

Source: Prime Studios White Paper on Synthetic Training Data Benefits

Technologies We Work With

Our datasets integrate seamlessly into your workflow:

Commercial Vision Platforms

- Cognex VisionPro

- Cognex In-Sight

- MVTec Halcon

- NI Vision

Custom ML Frameworks

- PyTorch

- TensorFlow

- Keras

- scikit-learn

- OpenCV

No matter what vision platform or ML framework you use, we deliver the missing defect data your AI needs.

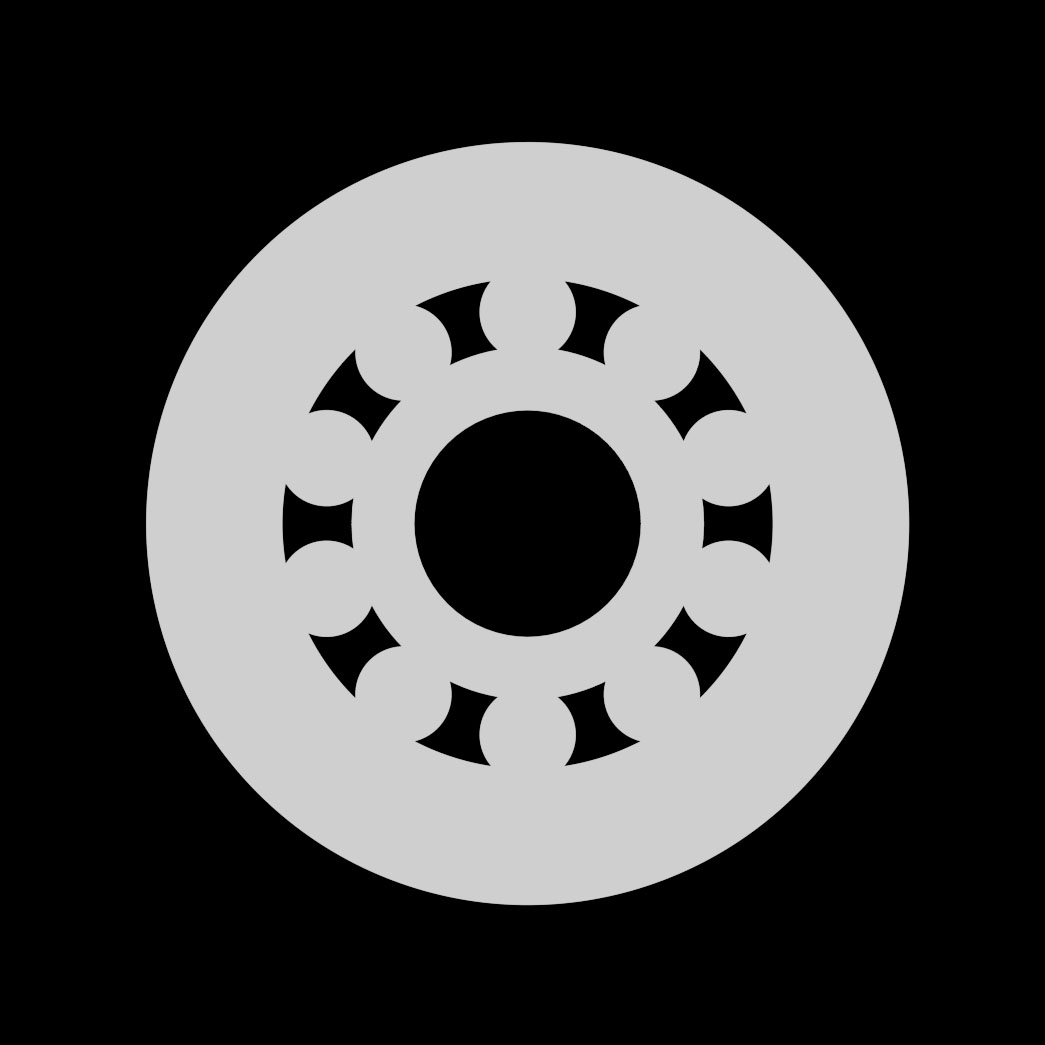

See the Difference

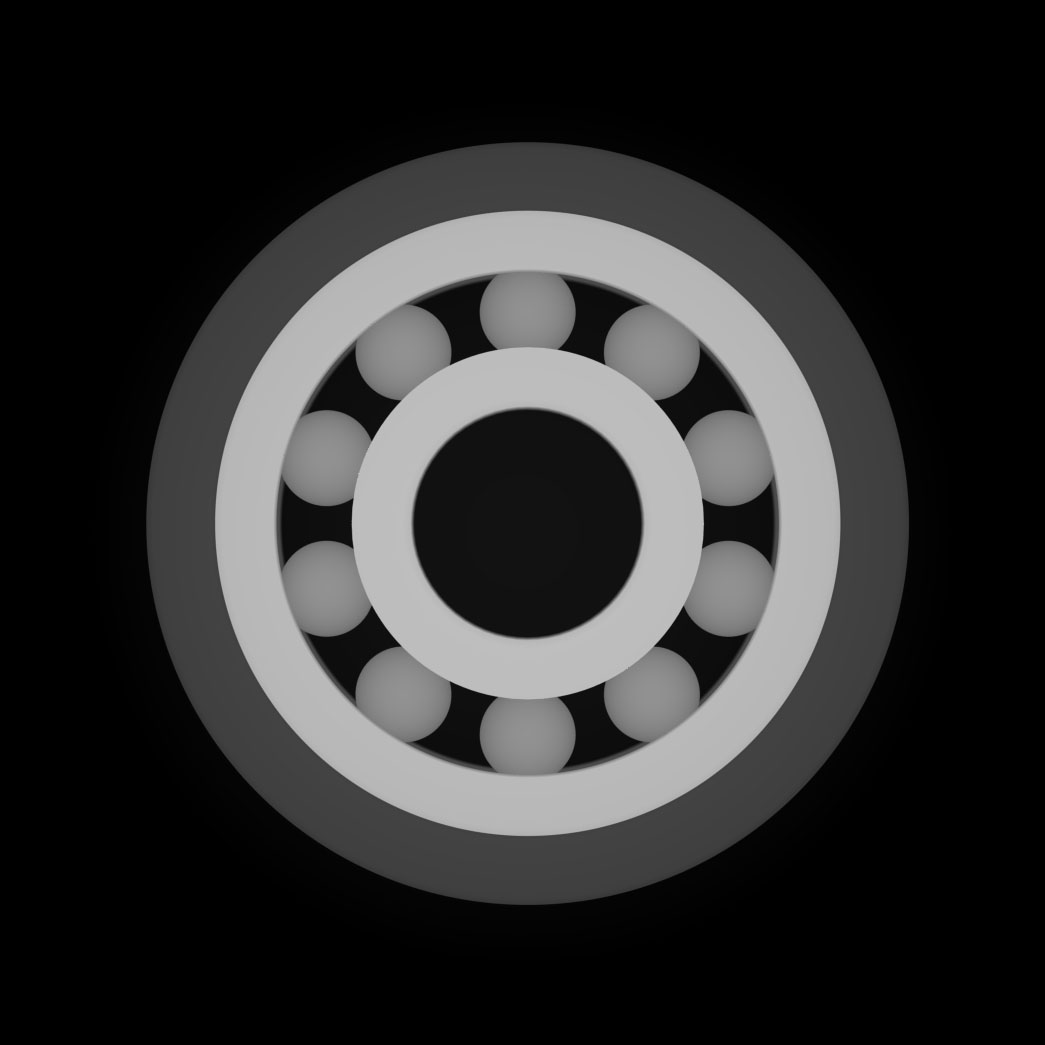

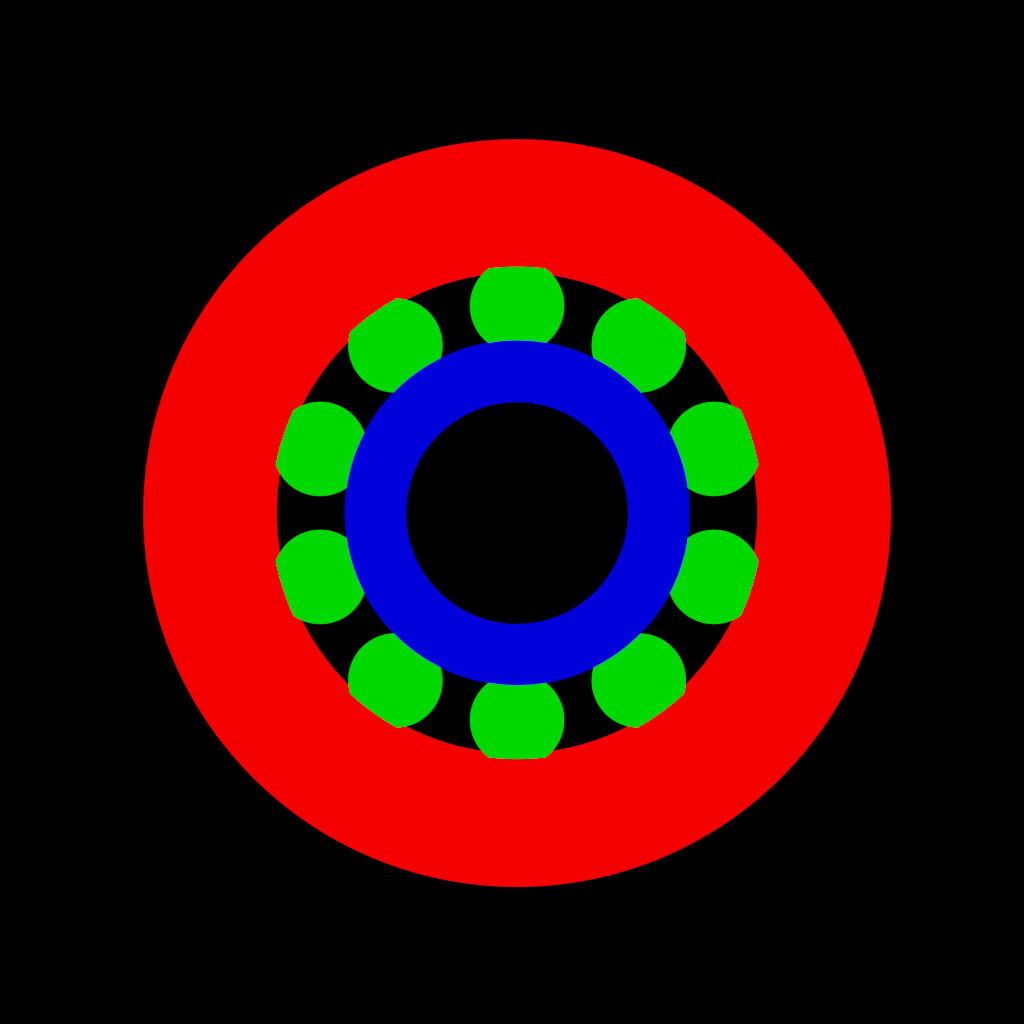

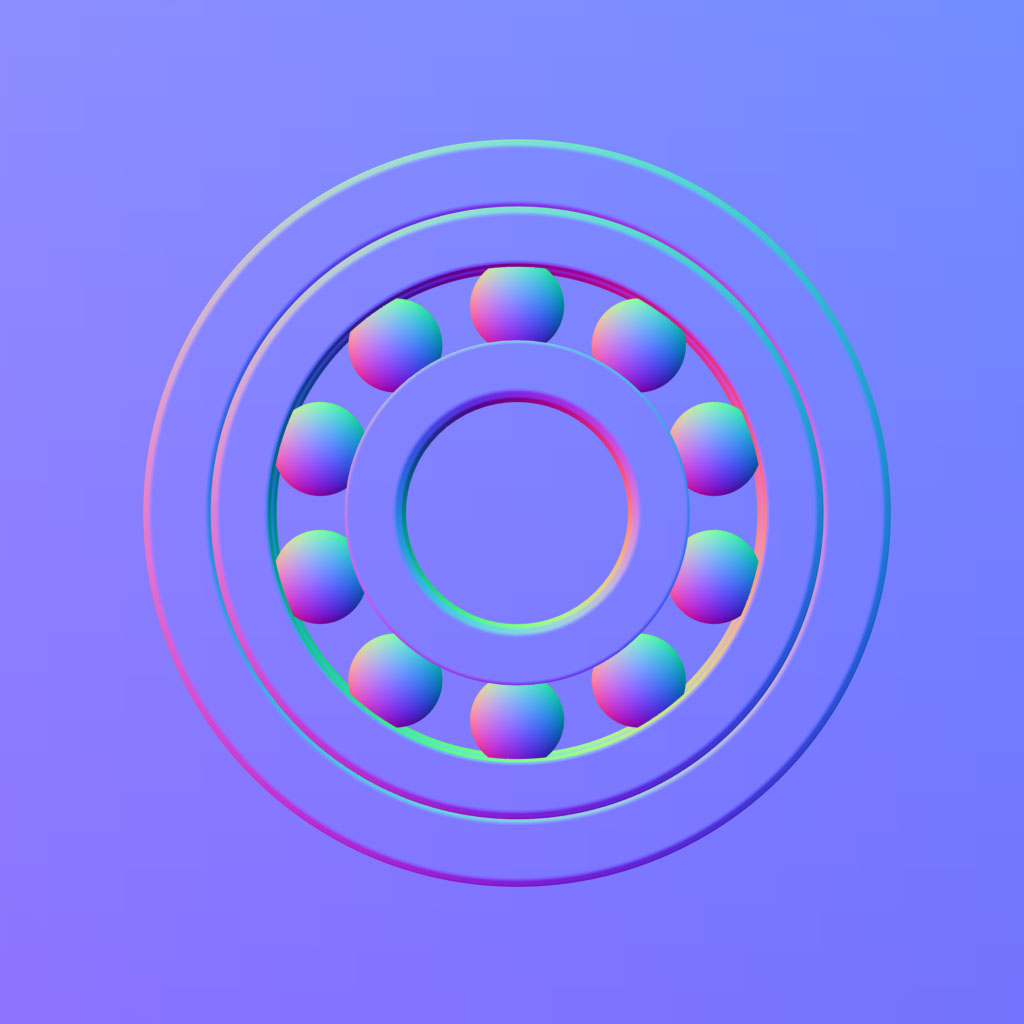

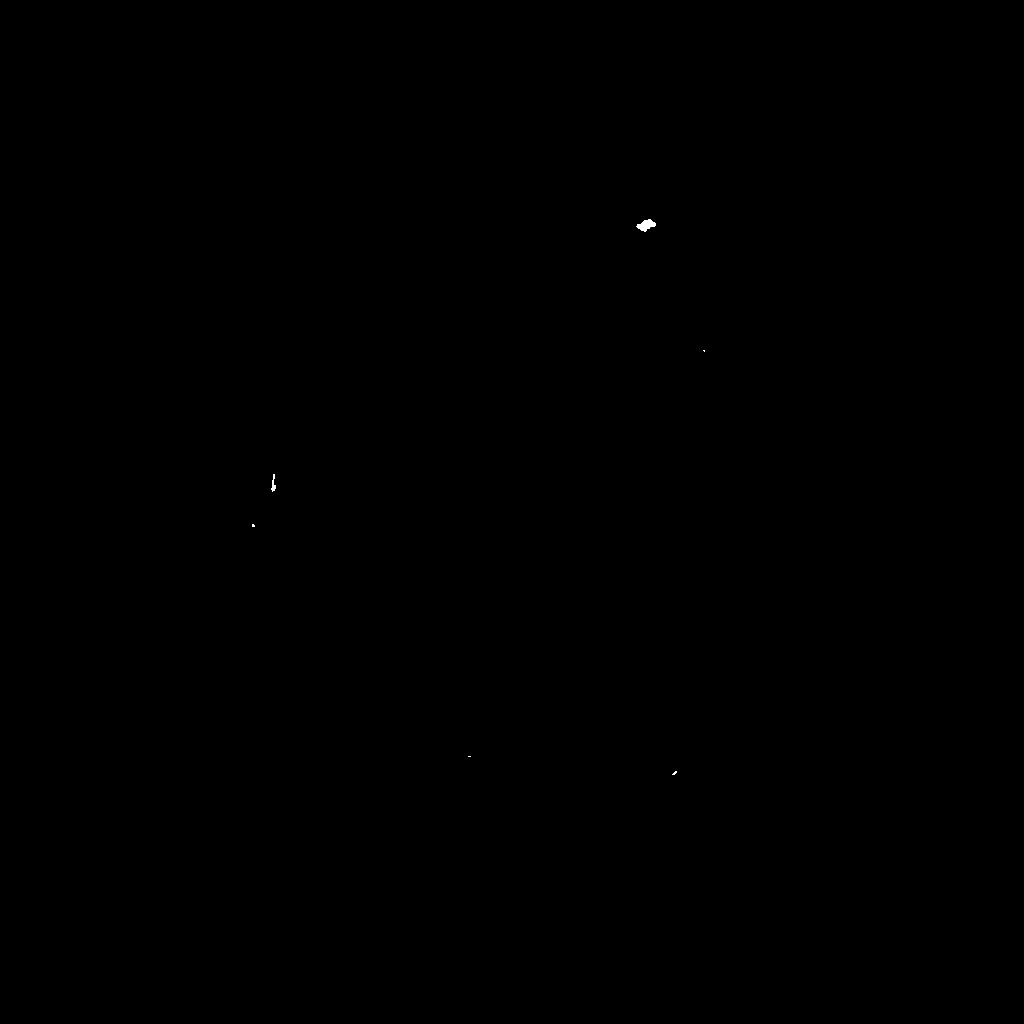

Explore our synthetic bearing dataset - the same object rendered with different data channels for comprehensive AI training

RGB Image

RGB Image

Object Mask

Object Mask

Depth Map

Depth Map

Segmentation

Segmentation

Surface Normals

Surface Normals

Defect Ground Truth

Defect Ground Truth

Multiple data channels from a single synthetic object provide comprehensive training data for robust AI models.

Who We Serve

We specialize in industries where defects are rare, parts are valuable, and reliability is mission-critical:

Medical Devices & Biotech

Implants, surgical tools, prosthetics

Aerospace & Defense

Precision components, composites, turbine blades

EV & Batteries

Cell inspection, contamination detection, specialty fasteners

Semiconductors & Electronics

Wafers, micro-components, advanced packaging

Luxury Goods & Watches

Micro-defects in surfaces and movements

Renewable Energy

Solar panels, turbine blades, structural parts

Frequently Asked Questions

Contact Us

Prime Studios LLC

26632 Towne Centre Dr Ste 300

Foothill Ranch, CA 92610

United States